COTS products for space missions

Scalable, cost-efficient, proven for space – commercial space missions with specialty glass

In the past, materials for space travel were often custom-made products for highly complex mission parameters. Developing and qualifying these customized components is time-consuming and expensive. Space materials also need to survive harsh conditions, with challenges including high levels of radiation. In this respect, factors like reliability, durability, safety, and robustness have been important in the material selection processes to date, as repairs in space are currently difficult, or even impossible.

With space missions increasingly becoming commercialized, these priorities have shifted somewhat. New Space materials need to be available at low cost and in large quantities to make these projects economically viable. COTS - standardized, industrially-manufactured products that can be produced in large quantities - are a key factor in making space commercialization less expensive and in speeding up solution development cycles.

Advantages of COTS and materials off-the-shelf for space

Standardized industrialized glass components - as COTS or materials off-the-shelf - have various advantages for astronomy projects and missions in space. These include:

One prominent example from the commercial space industry that illustrates this are satellite mega-constellations: Many companies are operating these large groups of hundreds or thousands of satellites that work together as one system. These are not individual high-end satellites with state-of-the-art, specially developed measuring instruments and electronics. Instead, mega-constellations involve thousands of small satellites that have been developed for one or a small number of tasks. Space companies usually use an iterative design that relies less on high-end technology and custom components and more on adequate, readily available technology and materials for the mission task. Although individual components can also be specially developed, they need to be scalable in terms of quantity as they are installed in a large number of identical satellites. Reliability, durability, and resilience are still important factors for the latest generation of satellites, but economic considerations such as cost and scalability are almost equally important. Finding the right balance is the challenge here.

Specialty glass and glass components for space applications, such as those offered by SCHOTT, are already meeting this challenge.

COTS glass for space are already a reality

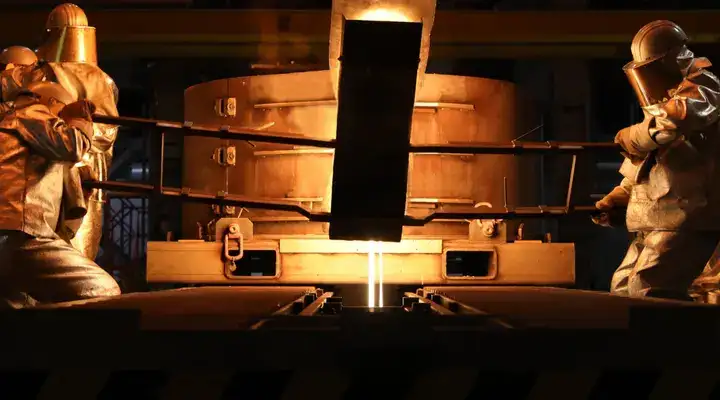

SCHOTT produces specialty glass components that are used in the aerospace industry, such as optical glass, electronic packaging, and cover glass for solar cells, and are available in standardized formats as COTS materials. SCHOTT has partnered with the aerospace industry for many decades and has optimized its products to meet their complex requirements. These glass products are now part of its standard portfolio and can be manufactured in large quantities for industrial applications. Depending on the product, SCHOTT can even do adaptations to these products for special mission parameters.

Glass-ceramic for precise imaging and positioning

With ZERODUR® mirror substrates, SCHOTT offers the leading material for telescope mirrors and other optical applications. This glass-ceramic was developed for precise imaging and positioning applications under extreme conditions. Thanks to its low thermal expansion, it is ideal for space applications. ZERODUR® is available in various sizes and shapes and with customized surface finishes. Although the glass-ceramic is produced based on each customer’s individual needs, the quantities are scalable thanks to SCHOTT's state-of-the-art manufacturing processes.

Learn moreSolar cell cover glass for more efficient energy generation in space

The SCHOTT® Solar Cell Cover glass family offers the best protection against radiation for solar cells in space. This ensures more efficient energy generation in satellites and other spacecraft over a long period of time. SCHOTT’s cover glass is space-proven and easily scalable thanks to optimized melting and production processes. That makes it the perfect solution for commercial spacecraft such as satellites in mega-constellations.

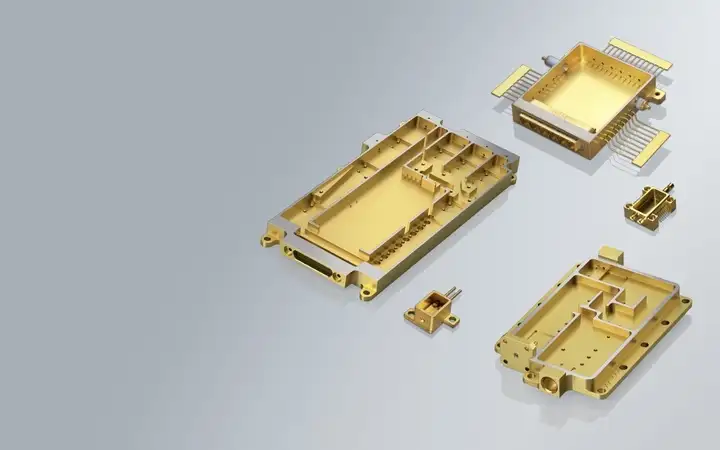

Learn moreReliable protection for critical electronics in space

Microelectronic packaging from SCHOTT meets the toughest requirements for performance and durability under extreme conditions - such as high pressure, high shocks, or large temperature fluctuations. In addition, SCHOTT has developed a lightweight version of its microelectronic packaging that helps significantly reduce the overall weight of satellites or other spacecraft. SCHOTT's microelectronic housings are available in large quantities. Thanks to their modular design, they can also be customized to meet special mission requirements.

Learn moreStandardized optical glass with superior properties

Thanks to melting processes that have been optimized over many decades, SCHOTT is able to produce various types of optical glass cost-efficiently and in large quantities. Here the company also provides customized solutions to meet the needs of its customers. These glasses deliver the best optical properties, and are radiation-resistant and space-tested.

Learn more