Unlocking the full potential of AI in Healthcare

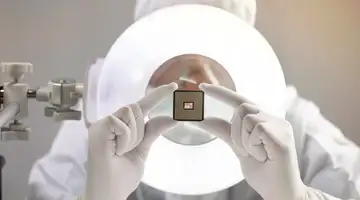

Fully realized AI systems could save millions of lives, so what’s holding it back? Glass core-based semiconductor packaging could solve the limitations of today's microchips, powering AI innovations in healthcare for precision and life-saving advancements.

Glass-based semiconductor chips could unlock AI's potential, transforming healthcare with precision, efficiency, and personalized care.

- AI is transforming healthcare by streamlining tasks, enhancing diagnostics, and giving doctors more time for personalized care.

- In cancer care, it mines vast datasets for earlier diagnoses, accurate risk assessments, and tailored treatments.

- Glass-based semiconductor packaging emerges as a solution to overcome the limitations of current microchips, offering the computational power needed to support AI's rapid growth.

- As AI evolves, advanced computing solutions utilizing glass core substrates with SCHOTT’s glass could be essential to unlocking its full potential—reshaping healthcare with precision, efficiency, and life-saving innovation.

Dr. Maria Knöbel has dedicated the majority of her life to healthcare. As an internationally trained doctor, she remains fueled by the passion that drove her to becoming a doctor in the first place: “The journey of improving patient lives that comes only through comprehensive, personal care,” she says. “It’s a journey I cherish deeply.”

For Maria, every moment spent with her patients can make all the difference. And yet, the busier the doctor got, the more she found herself frustrated by a growing sense of separation from her patients. The source of that separation? Routine, administrative paperwork was slowly but surely siphoning time away from the human beings she’d devoted herself to helping.

That is until recently, when her practice began utilizing artificial intelligence. “Just the other day I was in the middle of a particularly busy shift, almost running late to meet a new patient who was struggling with menopause,” she says. “But because the new AI tools were able to handle some administrative work I would’ve otherwise spent 10 minutes doing, I was able to spend 10 more minutes with that patient.”

Empowered to take her time back, those additional minutes allowed Maria and her patient to delve deeper into her concerns, discuss treatment options thoroughly, and develop a personalized lifestyle plan.

Meet Dr. Maria Knöbel

Dr. Maria Knöbel is the Medical Director and co-founder of Medical Cert UK. Based in London, UK, with an international board certification in Lifestyle Medicine, the general practitioner has practiced medicine in Switzerland, Austria, South Africa, and the UK throughout her career.

In addition to her clinical practice, she has authored peer-reviewed papers and medical textbooks, and has lectured at medical schools. Her work continues to shape the future of healthcare, focusing on personalized, accessible, affordable, and technologically enhanced medical solutions.

“She left feeling more informed and less anxious, and that meaningful interaction left me feeling grateful,” Maria says. “It's fascinating how a small-time extension, facilitated by AI, can profoundly enhance patient care and strengthen doctor-patient relationships.”

If just a few minutes can make a difference, then AI is just getting started. Beyond streamlining administrative tasks, it has the potential to rapidly reshape healthcare, from how we diagnose patients to how we treat them. Yet, to fully realize this potential, more powerful computing systems are necessary—and today's technology has hit its physical limit.

As AI demands more computational power, glass core substrates may be the key to unlocking the next phase of AI's evolution, particularly in healthcare, where massive data processing is critical to personalized care.

Transforming traditional systems

The high-density interconnects and heterogeneous packaging enabled by a glass core substrate.

In addition to handling administrative tasks, AI has made strides in diagnostics. “I’ve been in situations where AI tools have picked up on subtle details in medical scans that I might have missed,” Maria says. These interventions, which allow for more accurate diagnoses and earlier treatments, can be life changing.

This impact is particularly evident in cancer care. Adam Yala, an assistant professor at UC Berkeley and UCSF, is focused on developing machine learning methods to personalize cancer treatment. “The more I worked in the area of cancer research, the more I felt a massive unmet need,” Adam explains. “Even asking simple questions at top cancer centers, such as ‘How many patients with a subtype of cancer responded to a particular drug at that cancer center?’ remain infeasible to answer today.”

Meet Dr. Adam Yala

Adam Yala, PhD is an assistant professor of Computational Precision Health and Electrical Engineering and Computer Sciences at UC Berkeley and UCSF. His research focuses on developing machine learning methods for precision health and translating them to clinical care.

Dr. Yala’s tools have been deployed at multiple health systems around the world and his research has been featured in the Washington Post, New York Times, Boston Globe, and Wired. He obtained his PhD in Computer Science from MIT, and subsequently became a member of MIT’s Jameel Clinic and Computer Science & Artificial Intelligence Laboratory.

Even more frustrating, he adds, is that “a lot of the clinical tools we use to underpin national clinical guidelines, like cancer risk models, are awful at predicting risk.”

This is where Adam and his team believe AI can make a major impact. “Cancer is one of the most information rich areas of medicine, with gigabytes of data collected across routine patient care, but our clinical protocols rely on just a few bits of information,” he explains. “AI has the potential to mine this massive amount of data we already have to personalize care, which would enable us to catch cancer systematically earlier, improve diagnostic pathways, and optimize treatment protocols.”

Unfortunately, the sheer volume of data AI must process—particularly in healthcare, where Adam’s team deals with "gigabytes of data per person"—pushes the boundaries of what traditional computer chips can handle. AI systems are only as powerful as the hardware they run on, and the current hardware is at the physical limit of processing power.

“Computational power is a fundamental bottleneck in realizing the full potential of our data,” Adam says. As a result, he and his team spend a lot of time developing new algorithms to optimize the limited computer power they have – to "squeeze more out of them” – but there is only so much that can be done.

For decades, silicon technology-driven performance increases in computer chips have been the standard. They’ve gotten us to this point, and provided the computational power to give rise to AI in the first place. But for AI to evolve and realize its full potential, a new approach to chip technology is needed.

The rising energy demands of AI

AI’s rapid rise has led to an exponential increase in energy consumption, as today’s microchips lack the processing power to handle its demands efficiently. With AI being integrated into everything from personal devices to large-scale enterprise systems, this trend is accelerating at an unprecedented rate. The energy demands of training and running AI models are skyrocketing, raising concerns about sustainability and the long-term environmental impact.

By transitioning to more powerful and energy-efficient glass core-based semiconductor packaging, we can significantly cut AI’s energy footprint. This innovative approach offers a path toward making AI more sustainable without compromising its growth and potential.

Forging a new path

As AI systems advance, their demands push today's solutions to their limits, leading to challenges such as computational power, energy consumption, shrinkage, and warping—especially as manufacturers strive to pack more transistors into ever-smaller devices. To overcome these limitations, industry leaders are turning to a new material: glass.

Uniquely suited for next-generation semiconductor packaging, glass substrates offer ultra-low flatness for smooth, uniform surfaces—beneficial in processing and product design—and superior thermal and mechanical stability compared to organic materials. These properties enable glass to support advanced designs, enhance performance, and withstand higher temperatures and stress without compromise.

Additionally, glass core substrates can allow a significant increase in interconnect density, which is critical for data-intensive AI workloads that require numerous processor connections. By minimizing pattern distortion and dimensional instability, glass facilitates precise chip packages with dense interconnect layers, meeting the growing demands of AI.

Meet Dr. Christian Leirer

A physicist and 15-year veteran of the semiconductor industry, Dr. Christian Leirer is passionate about pushing the boundaries of semiconductor performance through innovative glass solutions.

As Head of Semicon Glass Solutions at SCHOTT, he leads a dedicated team in strengthening and advancing SCHOTT's excellent products for the semiconductor industry. Dr. Leirer is committed to supporting customers with best-in-class glass solutions that drive digital transformation in the age of AI.

Leveraging decades of expertise in materials science and advanced packaging, SCHOTT recently formed a specialized division dedicated to providing tailored solutions, high performance, and reliable supplies to the semiconductor industry.

Dr. Christian Leirer, an industry veteran with over 15 years of experience, leads SCHOTT’s semiconductor division. “Over the past decade, SCHOTT's specialty glass products have already played a key role in semiconductor manufacturing,” he explains. “Years of research and collaboration with industry leaders have prepared us to also play a key role in advanced semiconductor packaging -- the next technology step of the semiconductor industry.”

Nearly all computer chips manufactured today already encounter specialty glass from SCHOTT

Beyond its most recent innovations in the field of glass substrates tailored for the semiconductor industry, SCHOTT has been providing specialty glass solutions that are integral to the industry’s critical infrastructure for decades. The near-zero expansion material ZERODUR®, for example, is a crucial component of leading lithography machines worldwide -- where silicon wafers and exposure masks must be positioned with absolute precision to produce the finest structures for the most potent microchips. Throughout the process, SCHOTT products, including flexible light guides, ensure that the highest precision is maintained. Since these machines are used in all chip foundries and IDMs around the world, nearly all computer chips on earth encounter specialty glass from SCHOTT.

SCHOTT’s low-loss glass, for example, represents a technological breakthrough. “This advancement empowers manufacturers to push the boundaries of semiconductor performance," Christian explains, "enabling them to produce faster, more reliable chips that can handle the demands of next-generation technologies like 6G and AI.”

Glass core substrate-based packages, offering up to 40% better performance while consuming half the power of traditional microchips, could have a profound impact on cancer research like Adam’s -- wherein the size and complexity of datasets require vast computational resources.

“Cancer is one of the most information-rich areas of medicine, with gigabytes of data collected across routine patient care,” Adam says. "AI is the clear solution to derive insights from this data, but the current methods aren’t enough.” The enhanced computational power that glass core substrate-based devices offer could allow Adam’s team, and others in similar fields, to analyze this data more efficiently, leading to earlier diagnoses and more personalized treatment plans.

Innovation where it matters most

With devices getting smaller and more compact, glass enables effective packaging for efficient and powerful semiconductor chips.

AI has already begun transforming healthcare, but we are rapidly approaching a point where the hardware it relies on can no longer keep up. The limitations of the microchips we’ve relied on for decades threaten to slow progress, just as we’re beginning to see AI’s potential to improve human health. As AI continues to evolve, the power of glass could usher in an era of unprecedented healthcare precision and effectiveness—ultimately changing the outcome for patients facing diagnoses we consider fatal today.

“Right now, about one-third of cancers caught on mammograms are caught at a relatively advanced stage, resulting in worse outcomes and morbid treatment pathways,” Adam explains. “If fully capable AI models could flag high-risk patients earlier, we could intervene sooner to prevent advanced-stage diagnoses.”

Back on the hospital floor, Maria remains focused on the individual patients waiting to see her that day. Considering the impact she’s already felt from mere minutes, the doctor believes AI’s biggest impact on the healthcare industry will be in the relationship between patient and doctor.

“It's always combination of human experience and advanced technology that pushes healthcare forward,” she explains. “So while I don’t think AI will replace doctors, it’s poised to be a valuable tool in our arsenal -- enabling us to provide faster, more accurate, and personalized recommendations."

In simpler terms, “fully realized AI will allow doctors to give our patients the time and attention they deserve,” Maria concludes. “And that, at the end of the day, is what healthcare is all about.”