Waveguides for augmented reality

What are waveguides?

Waveguides are designed to guide the image emitted from the optical engine (projector) to the user’s eyes, while ensuring that the lens itself offers a clear and transparent experience – as if it’s not even there.

To that end, optical glass is needed to enable a compelling user experience. SCHOTT’s product portfolio supports the leading AR waveguide technologies to enable devices with high field-of-view (FOV), crisp images, and lightweight comfort.

What are smart glasses?

Smart glasses merge the digital world with the real world. Adding a layer of digital information on top of the user’s natural view opens up a wide range of opportunities in medicine, business, education, and entertainment – especially as smart glasses are meant to be worn all day. The complex technology behind augmented and mixed reality smart glasses involves waveguides made of optical glass.

What is the working principle of an AR waveguide?

Waveguides can confine light – in our case an image – and guide it to where it is needed. All waveguides have an incoupling area in order to receive light, and an outcoupling area in order to release it. It is common to use a micro-projector, or micro-display, to generate the digital image and channel it into the waveguide. The light then propagates through the waveguide and gets projected into the eye, creating a virtual image on a display that seems to be floating in free space.

A key feature of AR waveguides is their transparency and color neutrality. Since users have to look through the waveguide to see the virtual image, minimum obstruction of their natural field of view is desired. Therefore, waveguides are made of the highest quality optical glass, and that is where SCHOTT’s exceptional knowhow comes into play.

The main difference between augmented reality (AR) and virtual reality (VR) devices is the user experience. VR headsets purposely hide the real environment and completely immerse the user in an artificial digital world. AR/MR headsets, on the other hand, enhance the user’s perception of their real environment by adding digital content to it. This enables AR/MR headsets to be worn like regular spectacles, without obstructing the user’s field of view.

What role is optical glass playing in AR waveguides?

Due to its high refractive index, only optical glass can facilitate the fabrication of smart glasses with attractive form factor and high field of view. The optimization of other optical and physical properties enables devices with low weight and stunning image quality.What are the different types of AR waveguides?

There are basically three different approaches to guiding light with AR waveguides, and they are classified into the following categories: diffractive waveguides, reflective waveguides, and holographic waveguides.With an optical glass manufacturing and processing heritage of more than 140 years, SCHOTT offers solutions that meet the needs of any and all forms of AR waveguides.

1. Diffractive waveguide

Diffractive waveguides rely on nano-gratings on the surface of the in- and output area. Such gratings enable light to enter the waveguide from a digital image source, like a micro-projector. It is then trapped inside and can only exit the waveguide through a second surface grating located in front of the eye, where it will project the digital image right into it.

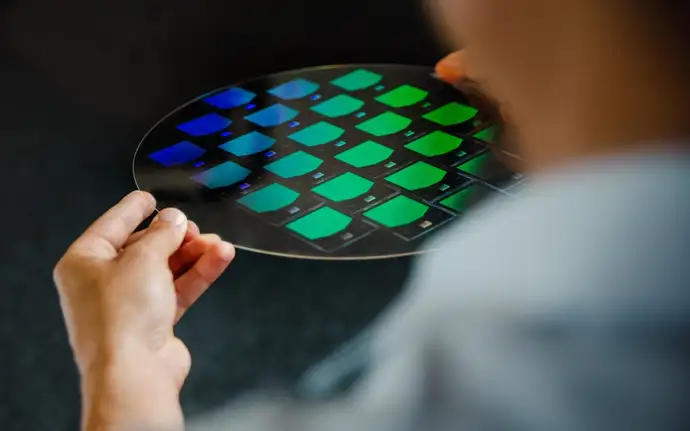

The backbone of a diffractive waveguide is optical glass with a high refractive index. From the broad portfolio of SCHOTT RealView® high-index glass wafers, customers can choose their substrate depending on their specific needs.

Different types of optical glass are available as blocks, which are cut into thin circular slices – available in different diameters – and polished with the highest precision. The larger the wafer’s diameter, the more eye pieces can be applied per wafer, reducing cost in the waveguide production process. The largest high-index glass wafers available have diameters up to 300 mm (e.g., SCHOTT RealView®).

2. Reflective waveguide

Reflective waveguides rely on a smart combination of internal semi-reflective surfaces. Like any other waveguide type, a digital image will be coupled in one of the outer corners and travel through the glass to be projected directly into the eye – thus creating a virtual image. As their name indicates, reflective waveguides use geometrical optics properties and do not consist of any diffractive optical elements, which makes their manufacturing approach very different. They are produced using common glass processing technologies like grinding, polishing, thin film coating, and bonding. SCHOTT’s in-house expertise and high production standards in those fields enable this complex technology to become widely available and cost competitive.

Producing reflective waveguides requires meeting the tightest tolerances, and SCHOTT not only achieves this need in high yield, but is currently expanding the AR reflective waveguide production setup in Penang, Malaysia as well.

3. Holographic waveguide

The holographic waveguide principle is quite similar to the diffractive waveguides. The main difference is the architecture of the incoupling and the outcoupling elements. Holographic waveguides are constructed using a liquid crystal based thin-film polymer embedded with nano-scale holograms that change state when activated with an electric current. When an image is projected onto the lens, the holograms guide the light through the surface before being directed towards the eye.

SCHOTT’s solutions for AR waveguides

SCHOTT has a vast knowledge and experience in developing and manufacturing glass wafers for the production of waveguides for AR devices. This is why many AR innovators utilize SCHOTT RealView® glass wafers to manufacture multi-layered RGB waveguides using the latest diffractive or holographic waveguide technology.In 2020, SCHOTT announced a partnership with AR optics company Lumus to manufacture their latest reflective waveguide platforms. This highly efficient product uses semi-reflective mirrors to guide the light through the glass into the user’s field of view. SCHOTT is currently ramping up mass-production capabilities in Penang, Malaysia, to allow for mass-adoption of reflective waveguide technology.

Glass quality has a direct impact on user experience