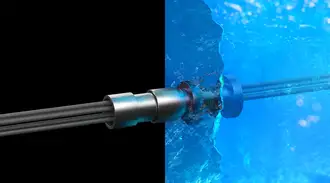

Eternaloc® oil and gas connectors, feedthroughs and penetrators

Eternaloc® connectors give sensitive electronics a hermetic protective barrier against the extreme environment for oil and gas. These components enable highly reliable electrical power and signal transmission for the entire product lifetime, reducing the need for costly maintenance.The challenges for oil & gas equipment

- Downhole drilling and subsea operations occur in one of the harshest environments on Earth.

- Oil and gas drilling equipment must not only survive but also operate flawlessly and safely under extremely high pressure and temperature as well as high voltages.

- Subsea equipment requires a strong barrier against water, gas, and various downhole substances to prevent failures and accidents.

- Long-lifetime designs are critical because maintenance is extremely costly when equipment is deep underground or on the ocean floor

- Electrical connectors and packages can be a potential weak point. Durability is critical since any failure can disrupt operations and compromise performance.

Uncompromised durability for extreme oil and gas environments

SCHOTT components are designed to withstand the challenging operating conditions of the oil and gas industry, including temperatures of 205 ºC and operating pressures of 20,000 PSI. We offer product variants designed for dependable power and signal transmission, whether underground or beneath the sea.Eternaloc® connectors – uncompromised reliability for power & signal transmission

- Superior pressure resistance

Up to 35,000 PSI / 2413 bar

- Extreme temperature resistance

From -170 to +450 °C

- High electrical performance

Up to 13,800 V & 1,500 A

Coax, triax, and fiber optic options available

- Unrivalled insulation resistance

Enabling > 10GOhm at 1000V

Relevant product:

Multi-chip-module (MCM) housings – superior protection for sensitive electronics

Apart from Eternaloc® connectors, SCHOTT also offers microelectronic package for oil and gas applications. Hermetic multi-chip module (MCM) housings are used for protective packaging of sensitive measurement and control electronics in harsh environment conditions. Simultaneously, built-in glass-to-metal sealed connectors enable power and signal transmission (electrical and optical) into and out of the package.

- Non-magnetic interference

Housings help the sensors function without magnetic disruption

- Efficient heat dissipation

Variety of heatsinking options available

- Superior shock and vibrational resistance

Remains hermetic in downhole drilling applications

- Different metal materials available

We offer GTMS in different metal materials such as non-magnetic titanium, robust Kovar alloys, and more.

Ulrich Dirr

Head of Sales Eternaloc®