Product variants of hermetic connectors and packaging for medical devices

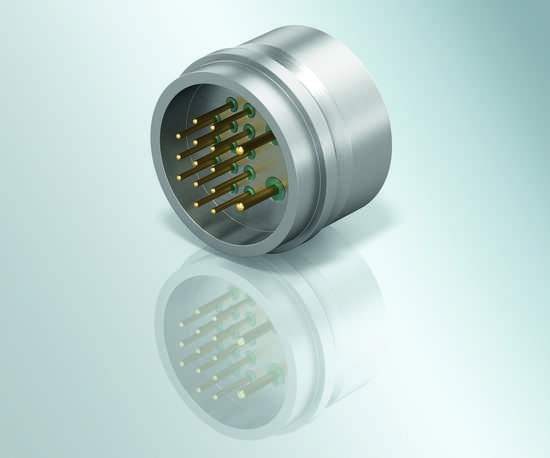

Sterilizable connectors

CHARACTERISTICS

SCHOTT offers connectors and packages in materials like stainless steel, titanium, and nickel-iron alloys, with in-house glass production for precision and flexibility. Key capabilities include:

- Laser welding

- Overmolding

- High-frequency

YOUR ADVANTAGES

- Comprehensive support:

We assist you from product development to high-volume manufacturing. - Optimized design:

Advanced simulation tools ensure the ideal size, shape, material, and interconnect configuration. - Enhanced functionality:

Subassemblies and customization tailored to your specific requirements.

Sterilizable windows

CHARACTERISTICS

Thanks to our in-house optical glass and sealing expertise, SCHOTT’s autoclavable hermetic windows provide highly effective and precise gas-tight interfaces for optical signal transmission.

Our customizable portfolio includes options for fiber optics, sensors, and LEDs. with choices in shape, material, and coatings to enhance light transmission. All products offer options for round or rectangular shapes, flat or angled windows, various materials, and enhanced light transmission with anti-reflection coatings and optical glass discs.

YOUR ADVANTAGES

- Comprehensive support:

We assist you from product development to high-volume manufacturing. - Optimized design:

Advanced simulation tools ensure the ideal size, shape, material, and interconnect configuration. - Enhanced functionality:

Subassemblies and customization tailored to your specific requirements.

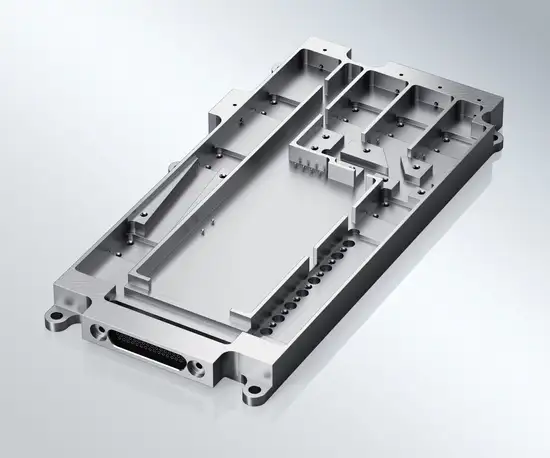

Sterilizable housings

CHARACTERISTICS

SCHOTT offers a wide range of autoclavable housing made from a variety of material combinations, including stainless steel, titanium, and nickel-iron alloys.

These fully customizable hermetic housings are temperature stable and resistant to thermal shock while also offering high electrical insulation. Various plating and post-processing options, such as laser welding and overmolding, can be used to add additional functionality or create subassemblies.

YOUR ADVANTAGES

- Comprehensive support:

We assist you from product development to high-volume manufacturing. - Optimized design:

Advanced simulation tools ensure the ideal size, shape, material, and interconnect configuration. - Enhanced functionality:

Subassemblies and customization tailored to your specific requirements.

Julia Hütsch

Sales Manager Medical Electronics