Photobioreactors

The industrial cultivation of algae relies on photobioreactor (PBR) technology, which depends on robust glass tubing that’s strong, UV-stable, bio-secure, and food-safe. SCHOTT’s PBR solutions provide the highest quality glass tubing with exceptional light transmission for reliable, long-lasting equipment.

Making the most of nature

Microalgae are regarded as an exciting source of vegan protein and nutrients used in food supplements for a wide range of health benefits. While microalgae are commonly found in nature, industrial cultivation is an efficient method of mass production, with photobioreactors (PBR) producing large amounts of consistent high quality and uncontaminated microalgae. DURAN® borosilicate glass tubing is widely used in PBR technology, providing the ideal environment for biomass production and water purification.

A global partner for PBR technology

SCHOTT has worked with some of the world’s leading algae cultivation companies, providing glass tubing in a wide variety of shapes, dimensions, and forms for the latest photobioreactors. Borosilicate glasses such as DURAN® deliver optimum light transmission, long life, consistent performance, and outstanding resistance, making them the number one choice for this rapidly developing sector.

How to choose a PBR?

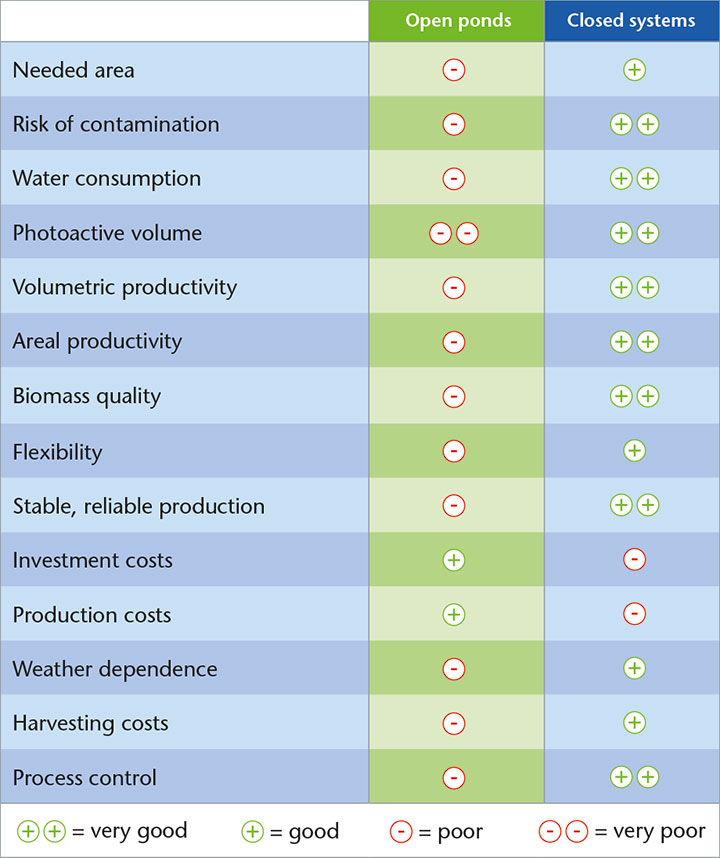

Phototrophic algae can generally be cultivated in two different ways, in open or in closed systems. The main difference between these two approaches is whether the algae solution is separated from the atmosphere or not. This has a crucial influence on which environmental impacts can affect the algae solution, and how well the algae cultivation can be controlled.

Advantages of closed systems at a glance:

-

Significantly higher productivity

-

Lower risk of contamination

-

Low water consumption

-

Low space usage

-

Excellent purity of the biomass (food grade)

-

High reproducibility of results

-

Constant and predictable production volume

-

Cost efficient harvest due to higher algae concentration

-

The possibility of an easy change of the cultivated algae

-

Low weather dependency

-

The possibility of a 24h production with artificial lighting

Methods

Algae can be cultivated in natural open ponds. However, in industrial production, artificial man-made ponds are usually found. These are typically flat and no deeper than 30 cm. In the water of these ponds, the algae are able to conduct photosynthesis and form biomass with the help of sunlight radiation. Open ponds are typically built in circular or raceway configurations. The open raceway pond is particularly common. The water is kept in motion, for example by paddle wheels, to intermix the algae.

The advantages and disadvantages of open systems

Open ponds are seemingly inexpensive and easy to build. However, danger of contamination, high water evaporation and low volumetric productivities are the main challenges, which lead to lower quality biomass output, large water uptake and costly downstream processes. Due to the constant water loss, the ponds often over salt over time. Some difficulties can be overcome by rooftops – however, at a higher cost.

With algae cultivation in closed systems, the cultivation solution in comparison to open ponds, is found in closed containers. The algae are therefore isolated from the immediate atmosphere. There are different forms of closed systems, they are mainly dominated by tubular and flat panel reactors. Other options are bags, coils or domes. The algae in closed systems, depending on their construction are set into motion by induced CO2 or pumps.

The advantages and disadvantages of closed systems

Closed systems initially require a higher investment and more knowledge about algae cultivation and production conditions. A closed system however, rewards one with significantly higher and especially reliable productivity and quality. This is because the impactful factors on cultivation in a closed system can be controlled accurately, one avoids bacterial contamination as well as dirt ingress, and the design permits a more effective use of light compared to open ponds. Additionally, closed systems are able to produce food grade biomass.

Closed cultivation methods come especially into consideration when high quality biomass is the main cultivation goal. Or when the algae need an accurately controlled environment for their development. This is the case when the intended use of the algae is for human nutrition, as an integral part of cosmetics or in pharmaceutical products. Ideally, these products are produced with a cultivation method that is food grade.

The geographical location of the algae cultivation and the available space are crucial for the choice of the cultivation method. These two factors potentially eliminate an open PBR. Furthermore, the significantly higher productivity and product quality as well as the enhanced calculability of production are also compelling reasons for using a closed cultivation method. There are numerous possibilities to choose from. The most common method of closed algae cultivation is the production in tubular PBRs, flat panel reactors and plastic bags.

Advantages of tubular PBRs at a glance:

Regardless of the container material, due to their geometry, tubular PBRs have the following advantages in comparison to other closed systems:

-

Higher productivity, due to optimal light usage in the tubes and simultaneous rare downtime.

-

Excellent calculability of production, due to their hardly every being unplanned production interruption.

These advantages are especially applicable to tubular systems made of glass.Glass systems additionally convince by:

-

Less biofilm formation, based on the low surface roughness of glass.

-

Easier cleanability with chemical and mechanical methods.

-

A very long lifespan of up to 50 years.

The lowest total cost of ownership at long operating periods.

Types of closed systems

Tubes made of glass or polymer are arranged vertically or horizontally. In most cases a pump enables the algae culture to pass through the tubular system, after which the culture is collected by a tank and recycled again into the tubular system. Tubular PBRs allow to plan production reliably, considering the processes, the amount and quality. Moreover, they are especially productive, due to them being able to use the available floor space and available light radiation perfectly. They are also relatively easy to clean.

This system uses plates made of glass or polymer. The plates are arranged vertically or horizontally with a thin layer of algae culture in between. The systems provide good lighting conditions. The systems however, suffer from heating problems and the tendency to form excess biofilm, especially when polymer plates are used. These biofilms are difficult to clean, as they are mechanically hard to access.

Plastic bags made of PVC or PE are fixed on special holder systems to intercept the culture supernatants. The investment costs are low, but strong biofilm formation followed by a frequent replacement of bags makes the process labour intensive and causes a lot of waste.

Closed tubular photobioreactors exist in laboratory and production sizes, as they are the only systems, which are able to produce high quality biomass for a cost efficient production of high end algae products like DHA, astaxanthin or spirulina. Algae for dietary supplements are best grown in closed systems as they provide a high degree of purity and productivity, which results in high quality of the final product. Furthermore, glass as a container guarantees that one can produce at a food grade level.

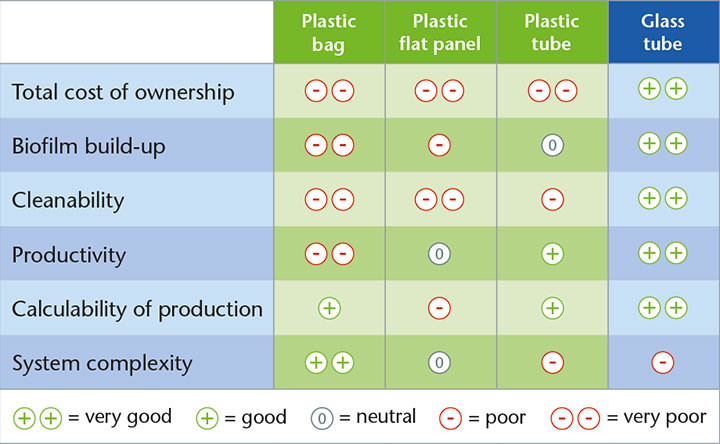

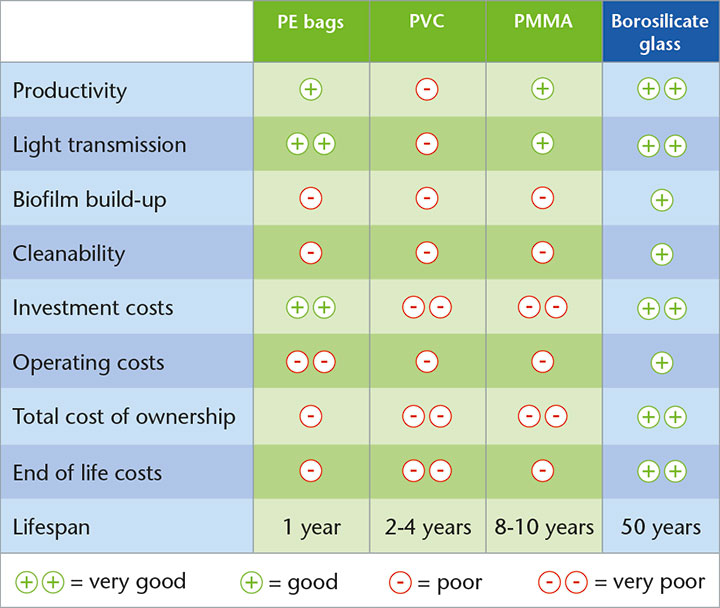

For further understanding: The table presents how well or poorly the alternatives perform regarding important evaluation criteria; from “very well“ (++) to “very poorly“ (--).

The central components of a closed PBR are the containers, in which the algae cultivation takes place. These containers can be made of either transparent plastic or glass. Both materials have advantages and disadvantages that have an influence on how often the production has to be interrupted and how high the PBRs total cost of ownership is. These factors then have an impact on the production costs of the algae.

Materials, from which PBRs are constructed

Polyethylene as a polymer variety is commonly used during algae cultivation in plastic bags. Bags of PE are particularly cost efficient at procurement. They typically however, need to be replaced at the latest, after one season or a year. This is due to them being easily covered by algae and their poor clean ability. The replacement is linked to material costs and lots of manual labor, and is therefore expensive.

Polyvinylchloride is typically used for flat panel and tubular reactors. The procurement costs of these systems at a given volume are cheaper than those systems made of glass. Due to PVC not being able to transmit the entire light spectrum, algae cultivation in these systems is less productive than with other materials. Furthermore, PVC degrades very quickly under UV radiation that it needs to replaced, when being used outside, every 2-4 years.

A plastic alternative for the manufacturing of tubular reactors is the use of polymethylmethacrylate (PMMA or Perspex). Compared to PVC, PMMA has the advantage of transmitting the entire light spectrum and hardly degrading. The lifespan of PMMA under solar lighting is approximately 10 years. However, a PMMA reactor of the same volume costs more than a glass reactor, which lasts 50 years. Additionally, the issue of biofilm formation is common for plastics such as PMMA.

Generally speaking, to ensure that photobioreactors made of plastic can produce at the same degree of efficiency, the plastic elements must be replaced within operation comparably often. When regarding longer operation periods of the reactor, this results in an unfavourable total cost of ownership. Moreover, some polymer varieties emit substances into the algae solution, resulting in algae cultivation at food grade not being possible.

Tubular PBRs are almost always made of borosilicate glass. This glass offers numerous advantages compared to other polymer varieties. It allows the entire light spectrum to reach the algae inside the tube. It is resistant against UV radiation, chemicals and salt water. This is the reason why tubes made of borosilicate glass are just as productive after 50 years as they are at delivery. They are also not very susceptible to biofilm formation. If this should occur at all, they can be easily cleaned.

Benefits of borosilicate glass:

Light transmission

-

Excellent light transmission

-

No solarisation or browning effect

-

No UV-protective additive or coating necessary to secure material properties

-

Lifetime of borosilicate glass > 50 years

Fire protection

-

Glass does not burn or give off toxic fumes

Leaching

-

Glass is a chemically highly resistant material. With plastic, depending on the polymer type, monomers or oligomers of hazardous substances such as bisphenol-molecules can be leached into the algae culture.

Cleaning

-

Mechanical stability allows continuous in-line cleaning with polymer pellets

-

Chemical stability allows cleaning in place (CIP)

-

Lower material and maintenance costs compared to quality polymer

Thermal stability

-

Tubes only: No need for expansion loops due to low thermal expansion.

-

Example: for 5.5 m long tubes and a temperature increase of 20 °C/ 36 °F the expansion of Borosilicate glass is only 0.36 mm/0.01’’ while polymers expand from 3.3-8.8 mm/0.13’’-0.35’’ depending on polymer type

Cost saving

-

Glass tubes can last fifty years and longer

-

Tubes only: Reduced number of racks due to high mechanical stability, which allows increased tube support distances without sagging of tubes

-

Example: double distance compared to PMMA tubes

-

Tubes only: Reduced number of connections due to long tube lengths of 5.5 m

Sagging (Tubes only)

-

No permanent deformation of glass tubes in contrast to polymer tubes

-

No remaining puddles in tubes when emptying the system

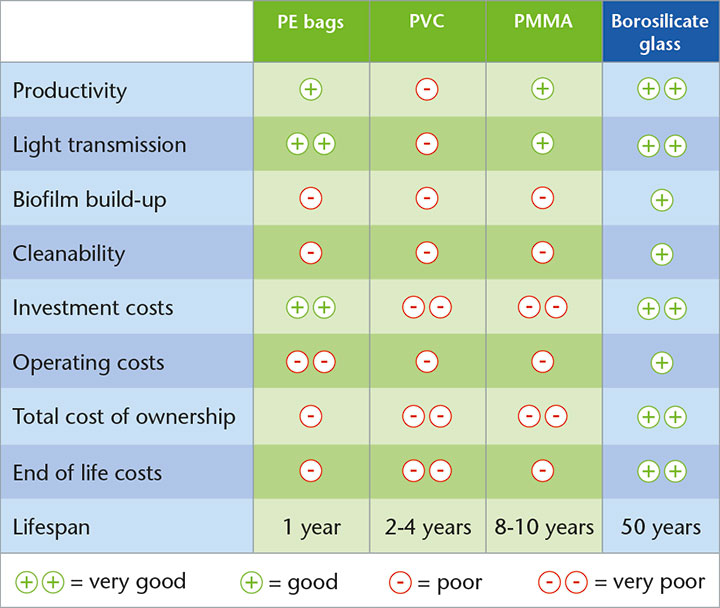

For further understanding: The table presents how well or poorly the alternatives perform regarding important evaluation criteria; from “very well“ (++) to “very poorly“ (--).

If your main concerns are the algae production costs, the lifetime of the PBR system and the total cost of ownership, you are definitely making the right choice with a tubular glass PBR. However, even when choosing among glass PBRs, there are significant differences. These differences can have a profound impact on the final system performance and therefore it is crucial that you are aware of them.

Advantages of high end glass at a glance:

-

Long lifespan of your photobioreactor of up to 50 years due to mechanically tension free and stable glass

-

Higher productivity through thinner tube wall thickness

-

Easy, tension free construction of the PBRs without gaps due to the same tube lengths

-

Low biofilm build-up

-

Rare production interruption because of cleaning

-

Integrated complete system due to coordinated components

Why high end glass is the best choice for your photobioreactor

The glass of the PBR tubes need to withstand numerous environmental impacts and cleaning processes, so that you can productively cultivate algae within them over many years. This is why SCHOTT uses borosilicate glass. This glass type is:

-

UV-stable: The glass’ light transmittance stays almost constant, even when being exposed to decades of solar radiation and UV radiation.

-

Chemically stable: Therefore, the glass tubes can be cleaned and disinfected with numerous chemical solutions to remove bio fouling within the reactor.

-

Salt resistant: This is especially important when planning on cultivating saltwater algae.

Find out more about the physical and chemical characteristics of borosilicate glass in our factsheet about borosilicate glass. Download the datasheet about borosicate glass.

The right type of glass is not the only relevant aspect when choosing glass tubes for a PBR. Just as important is the way the glass is manufactured, how the glass tube is processed and how the system as a whole is designed. Therefore, high end glass components with high productivity and excellent cost benefit calculation differ from lower quality ones.

Learn more about this topic: How using a PBR with high end glass components makes algae cultivation more economically viable

For further understanding: The table presents how well or poorly the alternatives perform regarding important evaluation criteria; from “very well“ (++) to “very poorly“ (--).

What our customers say

Superfood from the tube aquarium

With sustainable farming and the avoidance of animal products becoming important aspects of personal well-being, there is a rising interest in vitamin-rich, ecologically friendly superfoods like microalgae. Read more about the future of sustainable food production.

Learn more