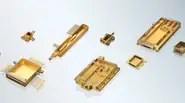

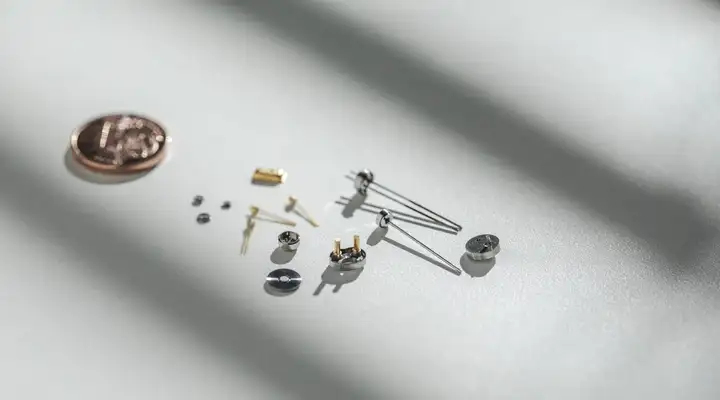

Customized enclosures and feedthroughs for implantable medical devices

Empowering medical progress for a healthier future

SCHOTT MiniCaps™ InVivo battery lids and feedthroughs are designed with decades of expertise in hermetic sealing and miniaturization. They offer reliability, biocompatibility, and RF transparency, supporting enhanced precision, longevity, and performance.

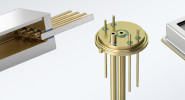

Discover SCHOTT’s expertise in hermetic glass-to-metal sealing and innovative electronic packaging solutions

Julia Hütsch

Sales Manager Medical Electronics