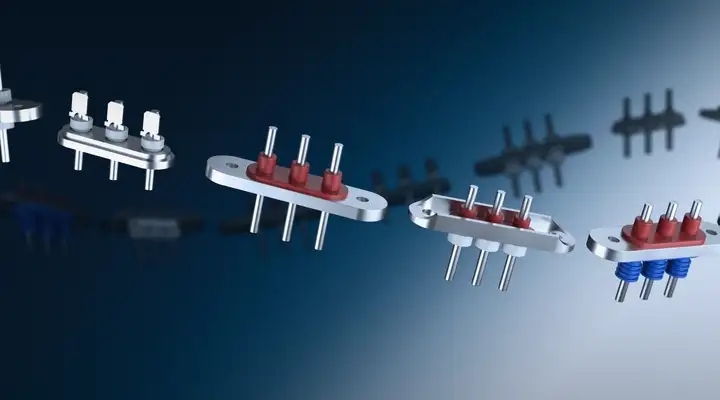

Automotive AC e-compressor terminals

CompRite™ e-compressor terminals for automotive air conditioning are designed to prevent refrigerant leakage and to maintain hermeticity under challenging operating conditions. These reliable glass-to-metal sealed components help ensure efficient and reliable compressor functionality.From standard to fully customized designs

The right combination of materials, features, and technologies enables optimally designed terminals that can address current and future challenges.Drawing on decades of expertise in the automotive industry and compressor technology, SCHOTT develops and manufactures hermetic seals for electric compressors that are custom-designed to meet the diverse needs of our customers.

Our key benefits

No matter the requirements, SCHOTT provides stable quality, even during high-volume production. Our components are optimized to your specifications and can tackle new challenges for electric compressor design, including high power, high voltage, and high current capabilities as well as resistance to high pressures.

Typical properties

- Insulation resistance: 1000 MΩ min. at DC 500 V

- Control of eyelet surface roughness: Ra 1.6, Rz 12.5

- Refrigerants that can be used: R134, R1234, R744(CO2), etc.

Expertise and production footprint

SCHOTT is a leading developer and manufacturer of electric compressor terminals for automotive air conditioners, with a highly competitive international production footprint. This empowers our customers to achieve greater success.Automotive expert

SCHOTT has been a reliable partner to the automotive industry for decades, delivering products tailored to a range of applications. CompRite™ compressor terminals are designed and made with expertise honed through our extensive experience in automotive components.- Over 50 years of experience in the automotive industry

- Leader in high-volume production with consistent, high-quality results

Advanced proficiency in e-compressor terminals

SCHOTT’s CompRite™ is a trusted brand with notable achievements, including:- No. 1 market share for e-compressor terminals (2023): The leading supplier for top e-compressor manufacturers.

- No. 1 in total production volume: Over 10 million units produced annually.

- 10+ years of experience: Extensive expertise in e-compressor terminal design, development, and manufacturing.

Stable supply system and global customer support

With two IATF 16949 (QS 9000/VDA 6.1) certified production sites, SCHOTT ensures a stable supply from prototype to mass production on a global scale. Additionally, our two R&D locations and worldwide sales offices provide timely customer support and technical assistance.

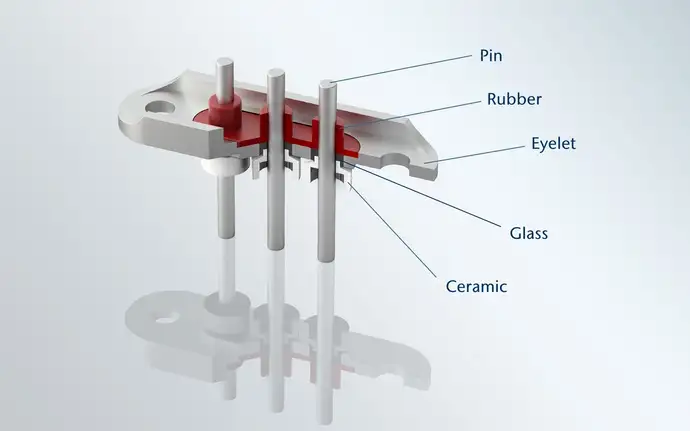

Carefully selected materials

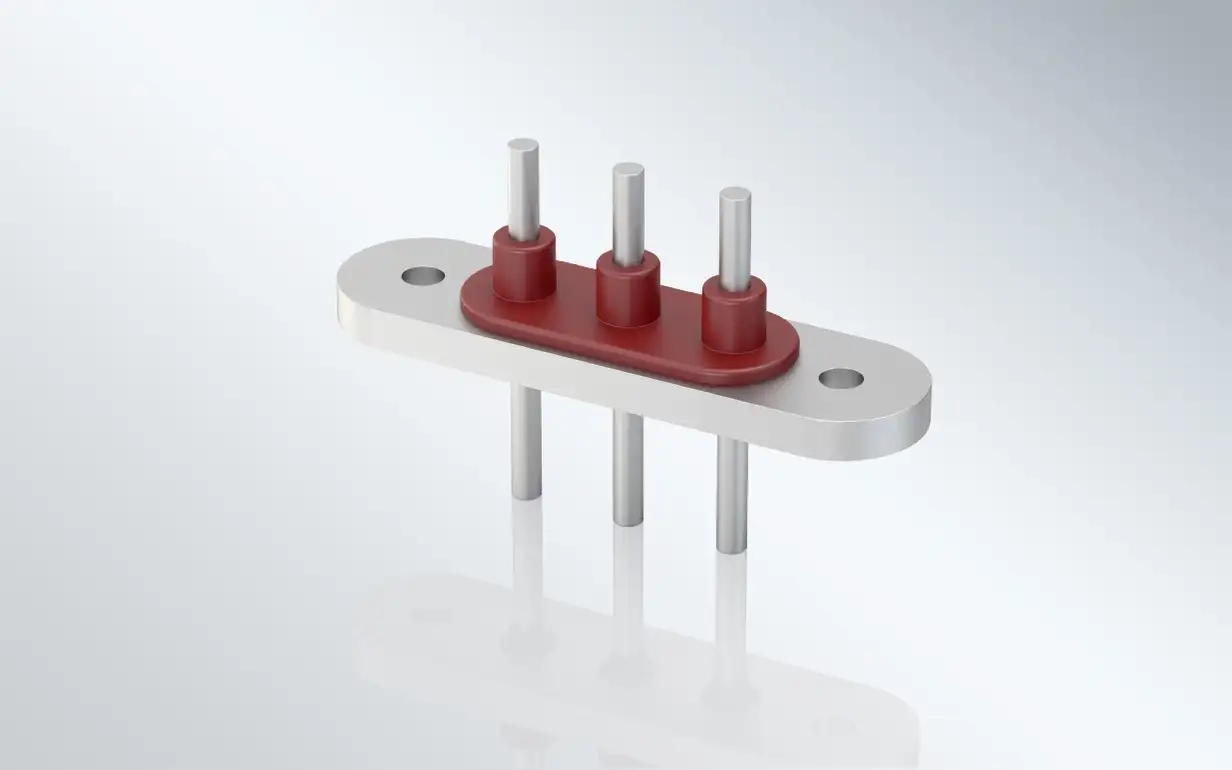

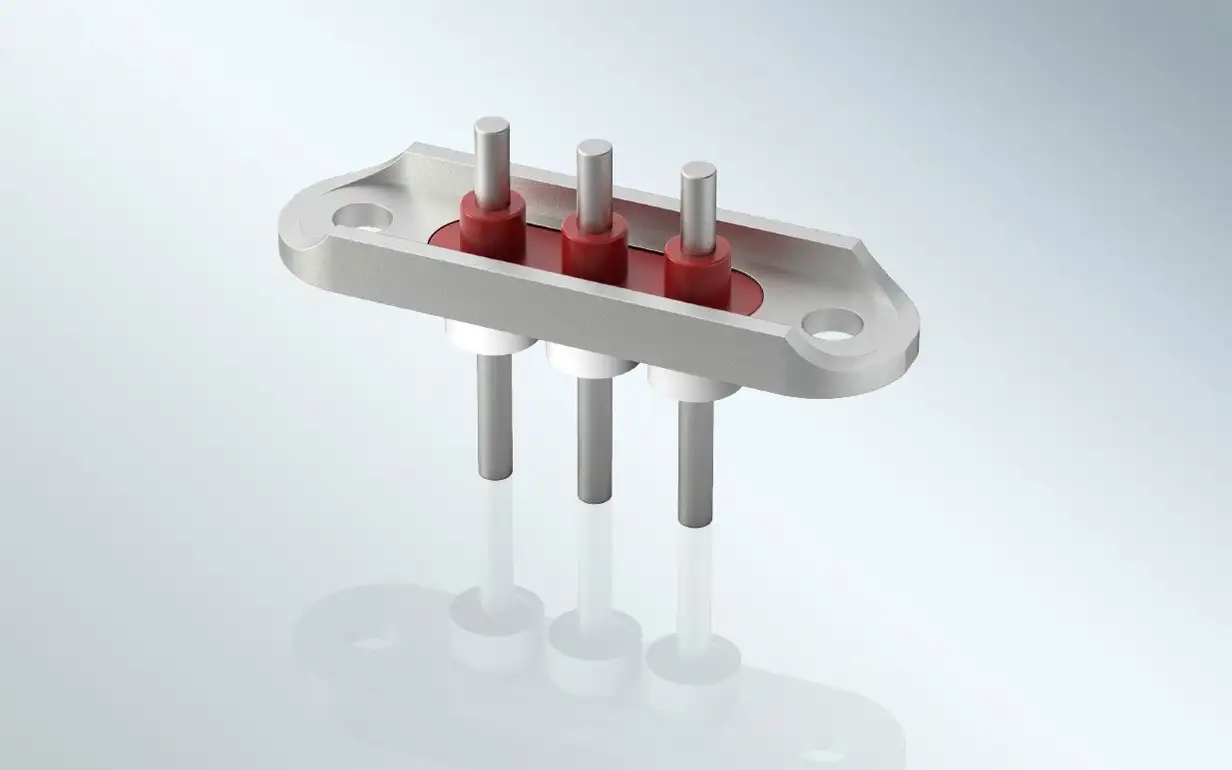

Materials are a key tool in overcoming the challenges of e-compressor terminals and electric automotive AC compressors. To support customers' needs, SCHOTT provides hermetic seals for optimal performance by selecting the best materials for insulation and optimizing eyelet shapes and pin designs.Materials

- Pin: Fe-Cr, Cr-Cu, Cu cored Fe-Cr

- Eyelet: Fe

- Glass: Soda barium

- Insulation Material: glass, rubber, ceramic

Our technical know-how

CompRite™ designs, optimized for your application, leverage our in-house expertise and technology to ensure efficient operation and consistent quality.Simulation technology

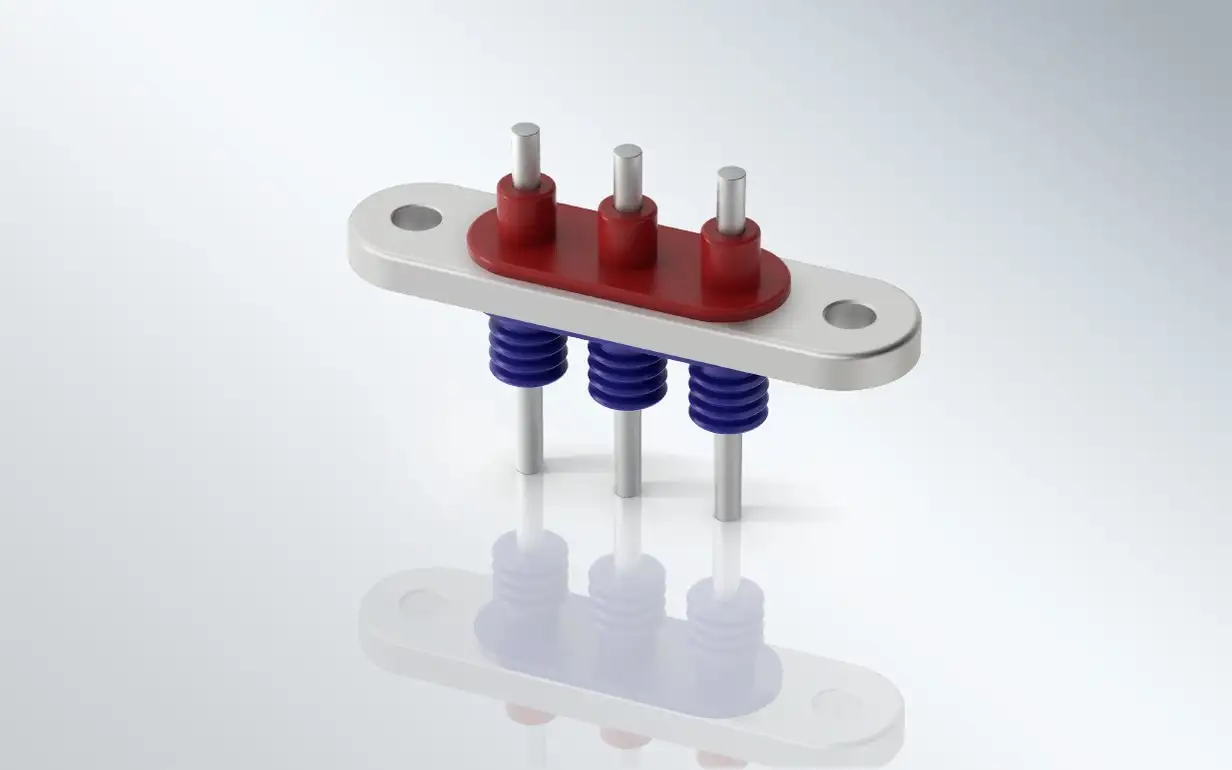

Although R744 (CO2) is the most environmentally friendly refrigerant for AC units, its use requires Glass-to-Metal seals that can withstand extremely high pressures, up to 20 MPa. Thanks to our advanced simulation technology, SCHOTT can provide a robust optimized design that handles these high pressures. This simulation technology is also highly effective for design calculations involving standard-pressure refrigerants like R134 and R1234. The image shows an example of using stress simulation to optimize eyelets for high-pressure applications.

Glass-to-metal sealing technology

As the leading glass-to-metal seal supplier, SCHOTT’s expertise and know-how enable high-quality seals.

Our strategic selection of metal and glass materials ensures durable and reliable seals.

CompRite™ compressor terminals use what is known as compression sealing technology. This involves selecting an outer housing metal with a coefficient of thermal expansion much higher than that of the glass and inner lead. During cooling, the housing will shrink firmly onto the glass and conductor to create a hermetic seal.

Mizuho Nakashima

Head of Sales Compressor Seal