Product Variants of Battery Lids and Connectors

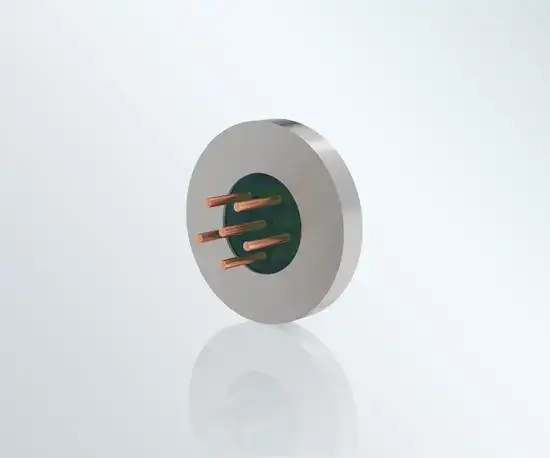

Lithium Primary Battery Covers

SCHOTT´s hermetically sealed battery covers enable the long-lasting performance of lithium primary batteries, even in harsh environment applications.

- Availability of standard sizes from AA, to C and D Cells.

- Customized designs (cylindrical and prismatic).

- High temperature resistance, ranging from -65°C to more than +150°C.

- Proprietary electrolyte-resistant glass specially developed for lithium primary chemistries, including lithium thionyl chloride (Li-SOCL2), Lithium Manganese Dioxide (LiMO2), Lithium Sulfur Dioxide (LiSO2), and more.

- Hermetic sealing reliably prevents humidity intrusion into the cell housing and electrolyte leakage.

SCHOTT battery covers are trusted by the battery industry worldwide with a proven lifetime of up to 25 years or more.

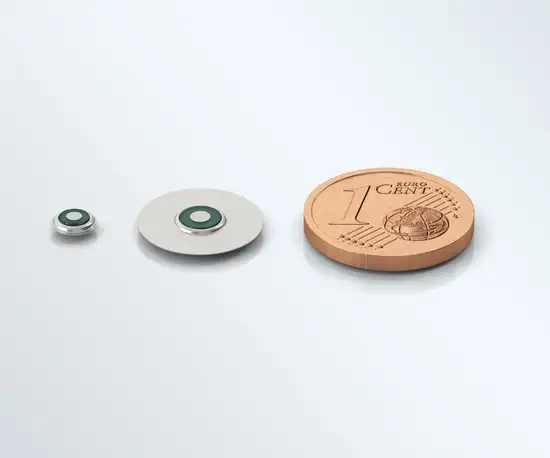

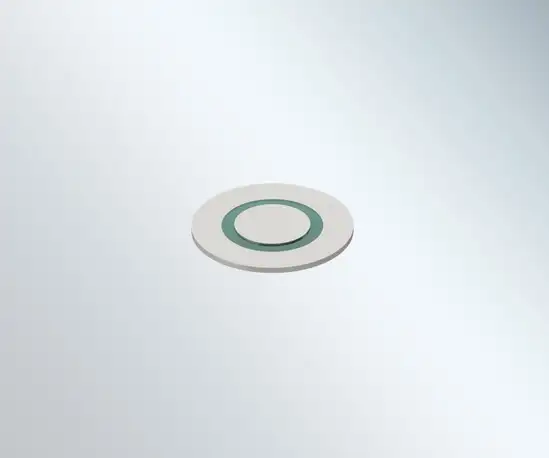

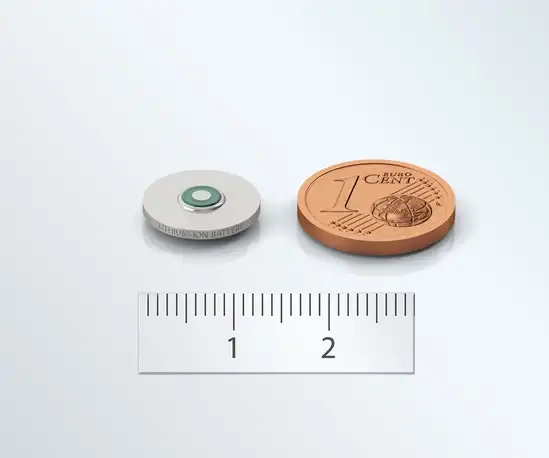

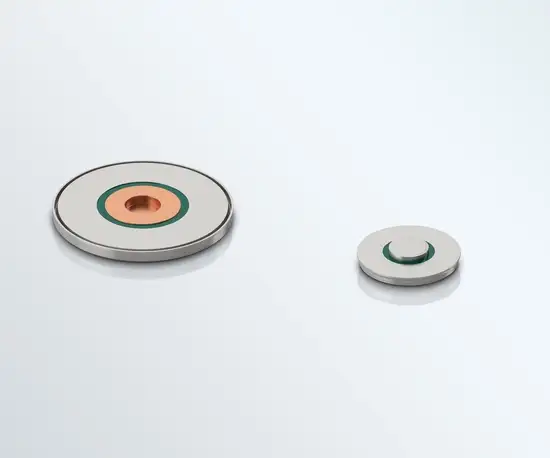

SCHOTT MiniCaps™

The microbattery lids are miniaturized, super slim and robust. They enable completely new microbattery designs with higher energy density for use in wearables, such as wireless earbuds, AR glasses, fitness trackers, as well as in medical and industrial applications.

- Extremely flat lid design – thinner & mechanically more robust than today’s standard

- Creates space for more electrolyte

- Lid and pins made of stainless steel

- High temperature resistance, from -40° C to over 125° C

- Electrolyte-resistant glass-to-metal sealing

- Customized lid diameters

- For coin cells and pin-type microbatteries

YOUR ADVANTAGES

With their extremely flat design, SCHOTT MiniCaps™ create extra space for more electrolyte in the cells compared to conventional polymer-sealed lids. This allows battery cell manufacturers to design tiny and robust cells with extended battery runtimes.

Lithium-Ion Battery Lids

SCHOTT’s battery covers are available in glass-sealed stainless steel or glass-to-aluminium-sealed (SCHOTT GTAS®) designs.

- Simplified, rugged lid design.

- High-temperature resistance, ranging from -60°C to more than +150°C, depending on design.

- Proprietary, electrolyte-resistant glass-sealing, especially developed for a wide range of lithium ion battery chemistries.

- Non-aging, fully hermetic design prevents humidity intrusion into the cell housing.

- Lifetime of up to 25 years.

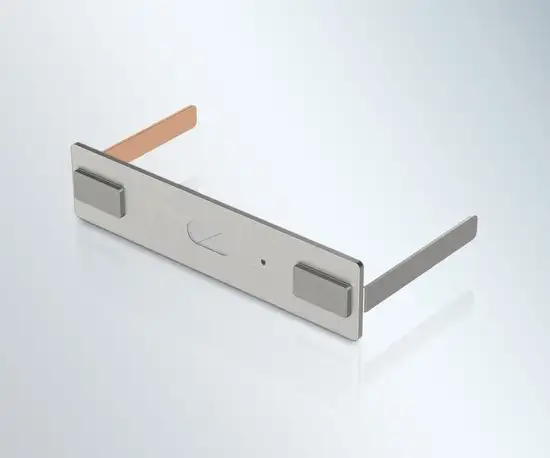

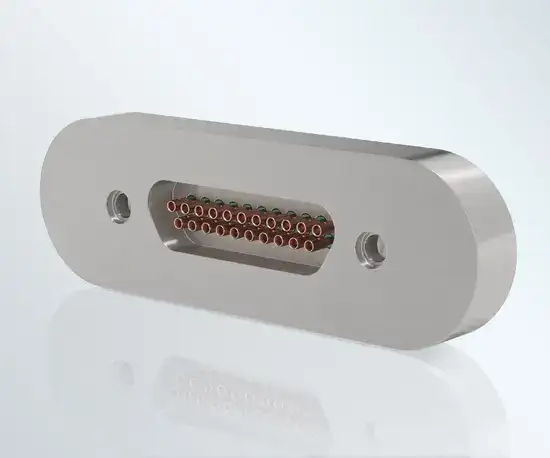

Battery Connectors

SCHOTT GTAS® or GTMS battery connectors create leak-tight high-power and low-power signal passthroughs for the battery modules used in electric vehicles. With their high mechanical robustness, chemical resistance, and high temperature resistance, they are particularly well suited for immersion cooled systems.

-

Made of metal and glass - non-aging, inorganic materials with proven resistance to standard cooling liquids and electrolytes (e.g. NMC, LFP)

-

Leak-tight over the lifetime of the battery module without corrosion, even for small pin pitches

-

Rugged design with high pressure resistance, based on compression sealing technology

-

High temperature resistance from -40°C to over +150°C

YOUR ADVANTAGES

Thanks to proprietary glass-to-aluminum (SCHOTT GTAS®) sealing technology and proven glass-to-metal seals (GTMS), SCHOTT® battery connectors not only provide a leak-tight connection, but also increase safety and reduce the risks of a thermal runaway. Moreover, these battery connectors are suitable for ultrafast charging.

Ultracapacitor Lids

SCHOTT´s glass-to-aluminum-sealed (SCHOTT GTAS®) ultracapacitor lid systems offer:

- High-temperature resistance, ranging from -40°C to more than +125°C.

- Electrolyte-resistant, non-aging glass seals that eliminate electrolyte dry-out.

- Up to 20% reduction in electrolyte volume.

- Reduction of capacity losses over time by up to 60%.

- Improvement of internal resistance by over 50%.

Ultracapacitors are now applied for larger-scale usage such as electric vehicles that rely on these components as they have far greater charge storage areas than standard capacitors.

High-power and renewable-energy applications also utilize ultracapacitors. These applications have pushed the demand for powerful, lightweight components that require little or no maintenance, are able to operate in harsh environments across a wide range of operating temperatures, and have high-power density and high reliability. SCHOTTs hermetic covers enable new ultracapacitor designs that push the boundaries of innovation even further.

Aluminum Electrolyte Capacitor Covers

SCHOTT´s glass-to-aluminum-sealed (SCHOTT GTAS®) caps for aluminium electrolyte capacitors offer:

- High-temperature resistance, ranging from -40°C to more than +125°C.

- Electrolyte-resistant, non-aging glass seals that eliminate electrolyte dry-out.

- Up to 20% reduction in electrolyte volume.

- Reduction of capacity losses over time by up to 60%.

- Improvement of internal resistance by over 50%.

Making use of these features, capacitor developers can design smaller capacitors with long operating lives, even for applications with high temperature ranges.

Carrissa T Ng

Sales Manager, Battery Solutions